Does the future of premium juice lie in a keg?

That the question even needs to be asked alludes to the bigger issue. High pressure processing has been the fuel driving the underlying growth of the premium juice category for the past decade, thanks to its ability to retain the raw product’s nutrient content and flavor while extending its shelf-life to be broadly viable at retail. The process has been so successful, one could argue, that it has made fresh juice somewhat less attractive in comparison: why take on headache of producing fresh juice on-site or transporting kegs with short shelf-life when packaged HPP juices deliver such a similar experience?

For large-scale juice operations, that indeed has mainly been the case. But for smaller brands with deep roots in their local markets, offering fresh dispensed juice provides valuable exposure and revenue. The recent collaboration between packaging maker Petainer, HPP technology firm Hyperbaric and organic juice brand Nourish Cold Pressed Juice, however, showed how these elements can potentially work together.

Operating from Organic Life Farm in Kennet Square, Pennsylvania, Nourish offers up to 26 seasonal varieties of organic juice in 16 oz. and 12 oz. bottles that are shipped nationwide. The company wasn’t in the keg business, but when its new grocery partner Giant Heirloom wanted to add Nourish to its in-store digital tap bar program, the equation changed.

The answer came in the form of Petainer’s single-use, fully recyclable PET Kegs, used primarily for dispensing beer and wine on tap. According to Nourish founder Francine Covelli, the key to unlocking compatibility with HPP was not the keg itself, but rather creating a custom made cap enclosure that could withstand the process and not leak. Having done so, Petainer completed a validation study that confirmed a 75-day shelf life for the kegs, which are compatible with standard draft equipment.

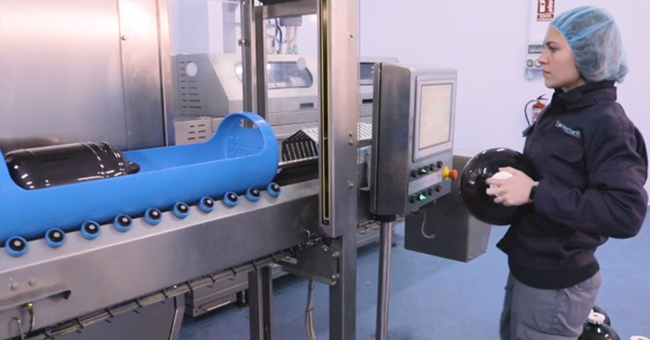

For a small business like Nourish, which does not use a co-packer, the ability to widen distribution for its juices in a relatively efficient way was a game changer. Petainer’s 20 liter (5.2 gallon) PET keg is compatible with four models of Hiperbaric’s HPP machines, with an output ranging from two to six kegs per cycle. According to Covelli, that’s about 42 cups of dispensed juice.

“Fortunately and unfortunately, no one’s ever run a keg under HPP,” said Covelli. “But think about all the labor that’s not involved. When you HPP it’s just one product, even though it’s 20 liters. It’s going through once, versus putting hundreds and hundreds of bottles in those canisters. It should be a lot more efficient in a lot of ways.”

Having been validated by its case study with Nourish, the keg’s potential to influence growth in the premium juice space is clear: Juices and beverages represent around 24% of global HPP applications, according to Hiperbaric. Andrew Brewer, director of technical services North America at Petainer, also noted that the company has successfully processed both coffee and almond milk in kegs, and also tested the process on beer. The company is also seeking to highlight its PET kegs as a more sustainable alternative to steel, requiring less fuel to transport, thanks to their lighter weight, and saving water because they don’t need to be cleaned and sterilized after use.

Along with claiming two to three taps placements across 14 Giant Heirloom tap bar locations, moving into kegs has allowed Nourish to dispense fresh product at events like the Firefly Music Festival in Delaware, which attracted around 50,000 attendees to its most recent edition in September. Having started her business as a brick-and-mortar operation, Covelli also sees the potential to use the kegs as a way to open a handful of simple, small-footprint (600 square feet) juice bars.

“I think we’re going to hit different markets and make an impact wherever we go, whether it’s at Firefly Music Festival or a large corporate venue or a college campus or at bars and restaurants,” she said. “So we’re seeing all kinds of people come our way that understand that they love our juice in the bottle, and that it’s a little more impactful [in a keg].”